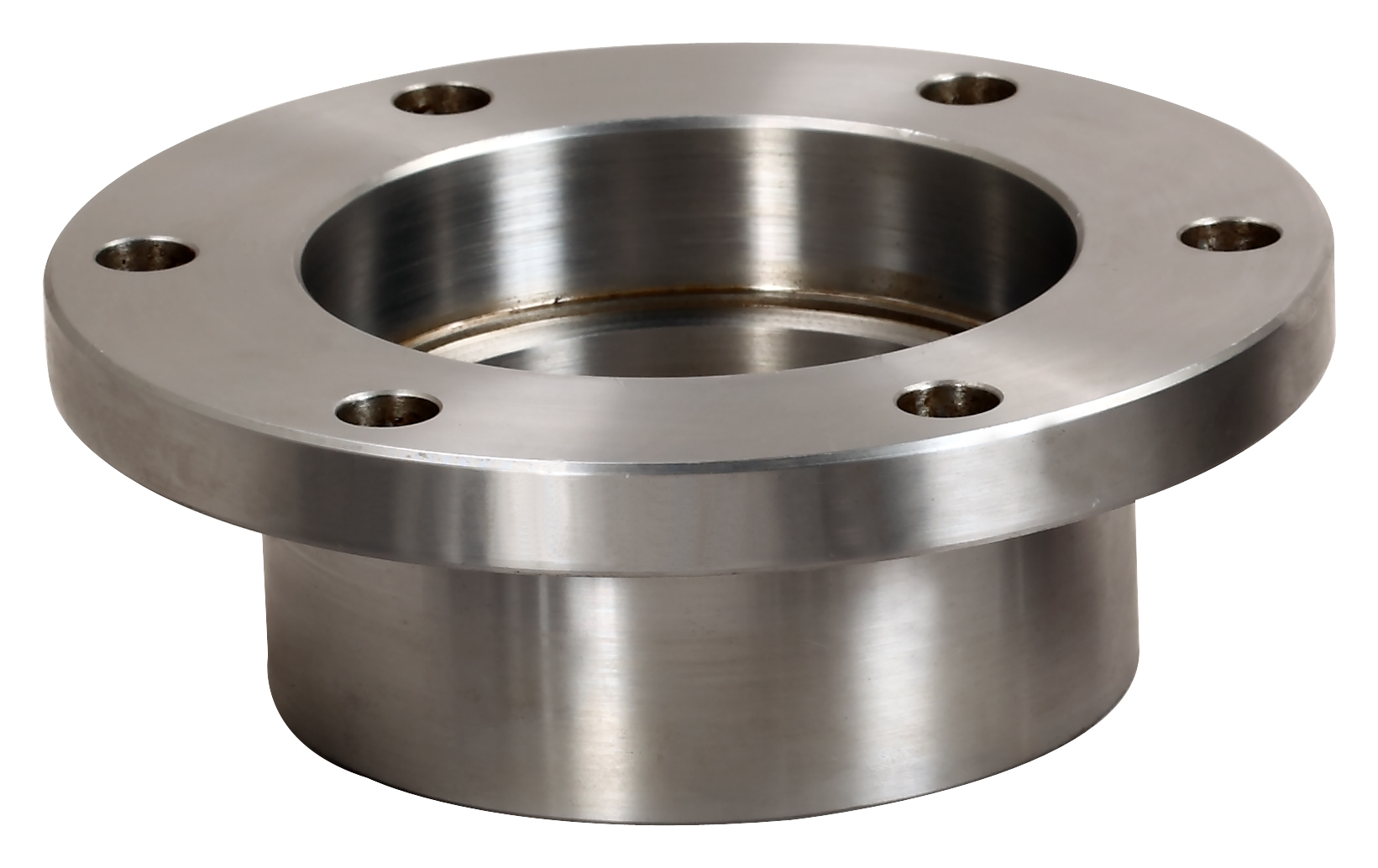

Inconel 625 Flanges Manufacturer, Supplier, and Stockists in India

Samay Steel and Engineering Co. is a reputed manufacturer, stockist, and exporter of high-performance Inconel 625 Flanges. Renowned for their excellent strength, corrosion resistance, and durability, these flanges are widely used in industries such as oil & gas, marine, chemical processing, and power generation. The Inconel 625 Flanges are designed to withstand extreme temperatures and corrosive environments, making them ideal for harsh industrial applications.

Our Inconel 625 Flanges are exported to various global markets including Oman, Qatar, Saudi Arabia, UAE, Kuwait, Spain, Germany, the USA, Canada, and several countries across Africa. With a commitment to international quality standards, we ensure our flanges meet ASTM and ASME requirements and are thoroughly inspected for performance and safety. We maintain a large stock of these flanges for quick and efficient delivery worldwide.

Inconel 625 is a nickel-chromium-molybdenum alloy with excellent resistance to pitting, crevice corrosion, and intergranular attack. These properties make Inconel 625 Flanges suitable for high-pressure and high-temperature applications, including offshore drilling, nuclear reactors, and chemical processing equipment. At Samay Steel and Engineering Co., we provide a range of flange types like weld neck, slip-on, blind, and socket weld flanges as per client specifications.

With a customer-centric approach and advanced manufacturing techniques, Samay Steel and Engineering Co. continues to serve global industries with premium Inconel 625 Flanges. Our dedicated logistics and support teams ensure timely delivery and complete technical assistance. Whether you require standard or custom sizes, our products are engineered to provide reliable performance and long-lasting service in demanding environments.

Inconel 625 Flanges Specifications

| Specification | Inconel 625 Flanges |

|---|---|

| Material Grade | Inconel 625 Flanges |

| Standards | ASTM B564 / ASME SB564 |

| Form | Weld Neck, Slip-On, Socket Weld, Threaded, Blind, Lap Joint Flanges |

| Size Range | ½” NB to 24” NB |

| Wall Thickness | Sch 10s, 40s, 80s, 160s, XXS |

| Length | Standard & Custom Lengths |

| Density | 8.44 g/cm³ |

| Tensile Strength | 827 MPa (min) |

| Yield Strength (0.2% Offset) | 414 MPa (min) |

| Elongation | 30% (min) |

| Hardness | Rockwell B88 maximum |

| Melting Point | 1350 – 1400 °C |

| Corrosion Resistance | Exceptional in oxidizing and reducing environments |

| Applications | Oil & Gas, Marine, Power Generation, Aerospace, Chemical Processing |

| Exported To | Oman, Qatar, Saudi Arabia, UAE, Kuwait, Spain, Germany, USA, Canada, Africa, Worldwide |

If you're looking for a reliable supplier of Inconel 625 Flanges, Samay Steel and Engineering Co. is your ideal partner. With years of experience and a global footprint, we serve clients in more than 25 countries with dependable solutions and exceptional service. Reach out to us today for competitive pricing, technical consultation, and fast delivery of top-grade Inconel 625 Flanges Pipes & Tubes.

Samay Steel and Engineering Co. has built a reputation for being a reliable supplier of Inconel 625 Flanges that meet the highest industry standards. Our experienced team of engineers and quality control experts ensures that each fastener undergoes rigorous testing to verify its mechanical, chemical, and dimensional properties. With our competitive pricing, excellent customer service, and commitment to quality, we continue to be the preferred choice for industries worldwide requiring top-tier Inconel 625 Flanges. Whether you need a single fastener or a large order, we are equipped to handle your requirements with professionalism and efficiency.

Chemical Properties of Inconel 625 Flanges

| Chemical Element | Inconel 625 Flanges |

|---|---|

| Nickel (Ni) | 58.0% min |

| Chromium (Cr) | 20.0% – 23.0% |

| Molybdenum (Mo) | 8.0% – 10.0% |

| Niobium + Tantalum (Nb + Ta) | 3.15% – 4.15% |

| Iron (Fe) | 5.0% max |

| Manganese (Mn) | 0.50% max |

| Carbon (C) | 0.10% max |

| Silicon (Si) | 0.50% max |

| Phosphorus (P) | 0.015% max |

| Sulfur (S) | 0.015% max |

Mechanical Properties of Inconel 625 Flanges

| Mechanical Property | Inconel 625 Flanges |

|---|---|

| Tensile Strength (MPa) | 827 MPa minimum |

| Yield Strength (0.2% Offset, MPa) | 414 MPa minimum |

| Elongation (%) | 30% minimum |

| Hardness (Rockwell B) | 88 RB (Max) |

| Modulus of Elasticity (GPa) | 207 GPa |

| Poisson's Ratio | 0.30 |

| Shear Modulus (GPa) | 83 GPa |

| Density (g/cm³) | 8.44 g/cm³ |

| Reduction of Area (%) | 40% minimum |

| Melting Point (°C) | 1350 – 1400 °C |

Types of Pipes and Tubes

Applications & Uses of Inconel 625 Flanges

- Inconel 625 Flanges used in Sugar Industry.

- Inconel 625 Flanges used in Power Industry.

- Inconel 625 Flanges used in ShipBuilding Industry.

- Inconel 625 Flanges used in Mechanical and Plant engineering.

- Inconel 625 Flanges used in Food, Beverage, and Dairy.

- Inconel 625 Flanges used in Oil and Gas Plant.

- Inconel 625 Flanges used in Process Instrumentation.

Cities we supply Pipes & Tubes in India :-

| Inconel 625 Flanges Supply: | |||||

|---|---|---|---|---|---|

| Bengaluru | Chennai | Hyderabad | Kolkata | Mumbai | Pune |

| Bhopal | Sri City | Jamshedpur | Hosdurg | Lucknow | Noida |

| Ahmedabad | Delhi | Raipur | Jaipur | Surat | Salem |

| Jamnagar | Bhubaneswar | Sivakasi | Rajahmundry | Thiruvananthapuram | Tiruppur |

| Bhiwandi | Bokaro Steel City | Bharuch | Vijaywada | Firozabad | Rajkot |

| Cochin | Ludhiana | Durgapur | Panna | Panipat | Raipur |

| Bareilly | Channapatna | Kharagpur | Peenya | Pimpri-Chinchwad | Nashik |

| Bangalore | Indore | Haldia | Moradabad | Varanasi | Rourkela |

| Bhopal | Sri City | Jamshedpur | Hosdurg | Lucknow | Noida |

| Bareilly | Coimbatore | Kannur | Nagpur | Vadodara | Rudrapur |

| Agra | Bhagalpur | Bhilai | Thane | Kanpur | Haldia |

| Angul | Dibrugarh | Gwalior | Patna | Trivandrum | Pithampur |

Countries we export Pipes & Tubes worldwide :-

| Inconel 625 Flanges Exporter: | |||||

|---|---|---|---|---|---|

| United States | South Africa | Malaysia | Bangladesh | Turkey | |

| Bahrain | Qatar | UAE | Africa | China | |

| Nigeria | Mexico | Canada | Venezuela | United Kingdom | |

| Egypt | Jordan | Portugal | Russia | Vietnam | |

| Kazakhstan | Thailand | Spain | Romania | Philippines | |

| Hongkong | Taiwan | Japan | Ukraine | Chile | |

| United States | South Africa | Malaysia | Bangladesh | Turkey | |

| Australia | Brazil | Germany | Singapore | Sri Lanka | |

| Iran | Saudi Arabia | Oman | Kuwait | Netherlands | |

| Belgium | France | Italy | South Korea | Poland | |

| Costa Rica | Israel | Iraq | Madagascar | Morocco | |