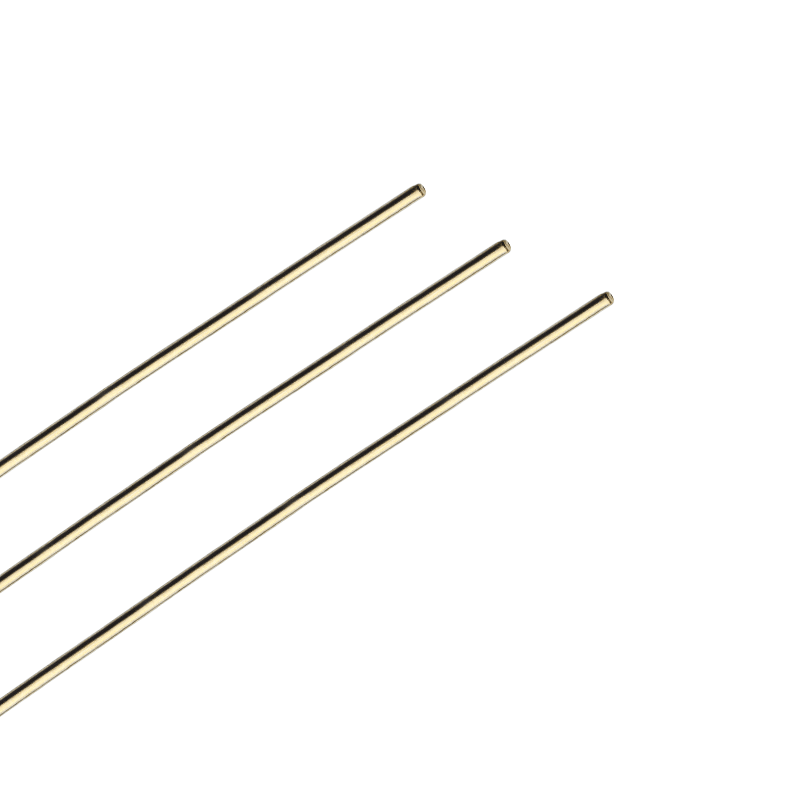

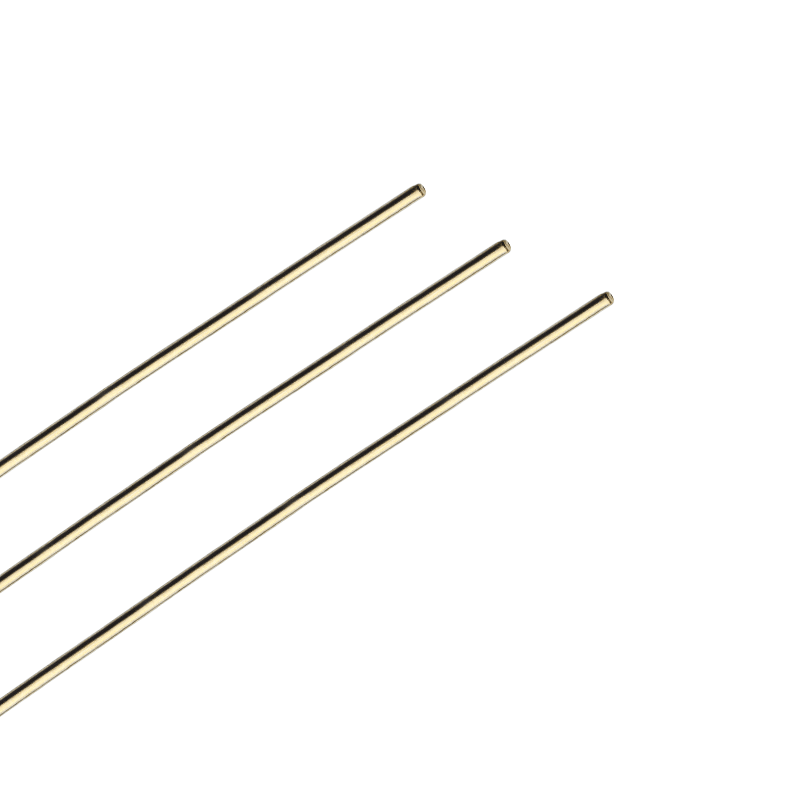

Nitinol Wire Manufacturer, Supplier, and Stockists in India

Nitinol wire, an alloy of nickel and titanium, exhibits unique properties that make it a valuable material in various industrial manufacturing applications. Primarily known for its shape memory and superelastic capabilities, Nitinol wire can return to a predetermined shape when subjected to specific temperature changes. This characteristic allows for innovative applications in sectors such as medical devices, robotics, and aerospace, where precision and adaptability are paramount. Furthermore, its biocompatibility makes it particularly suitable for medical implants and surgical instruments, enhancing patient safety and recovery outcomes.

One of the key properties of Nitinol wire is its high corrosion resistance, which ensures durability and longevity in harsh environments. This quality is especially beneficial in industries like oil and gas, where exposure to corrosive substances is common. Additionally, Nitinol wire possesses remarkable mechanical properties, including high tensile strength and excellent fatigue resistance, which contribute to its reliability in demanding applications. The combination of these properties allows for the development of lightweight yet strong components that can withstand significant stress and strain.

The advantages of using Nitinol wire extend beyond its physical properties. Its unique thermal behavior enables the design of devices that can function effectively under varying temperature conditions. For instance, in the field of robotics, Nitinol wire can be utilized in actuators that mimic muscle movement, providing a more natural motion. In the medical field, the use of Nitinol in stents and guidewires has revolutionized minimally invasive surgeries, offering improved performance and patient comfort. Overall, the versatility of Nitinol wire opens new avenues for innovation across multiple industries.

In summary, Nitinol wire stands out in the realm of industrial manufacturing due to its exceptional properties and diverse applications. Its ability to undergo phase transformations in response to temperature changes, coupled with its strength and corrosion resistance, makes it an ideal choice for high-performance components. As industries continue to explore advanced materials, Nitinol wire will likely play a crucial role in driving technological advancements and improving product performance across various sectors.

Specification Table

| Specification |

Nitinol Wire |

| Material Grade | Nitinol Wire |

| Standards | ASTM F2063, AMS 4956 |

| Form | Wire |

| Size Range | 0.1 mm – 3 mm |

| Wall Thickness | Not Applicable |

| Length | Single Random, Double Random |

| Density | 6.45 g/cm³ |

| Tensile Strength | 900 MPa |

| Yield Strength (0.2% Offset) | 600 MPa |

| Elongation | 10% |

| Hardness | Rockwell B85 |

| Melting Point | 1300°C |

| Corrosion Resistance | Excellent in marine & chemical environments |

| Applications | Medical Devices, Robotics, Aerospace |

| Exported To | USA, Japan, Germany, China, Canada |

Chemical Properties Table

| Chemical Element |

Nitinol Wire |

| Nickel (Ni) | 55.8% |

| Chromium (Cr) | 0.0% |

| Iron (Fe) | 0.3% |

| Manganese (Mn) | 0.0% |

| Carbon (C) | 0.0% |

| Silicon (Si) | 0.0% |

| Other elements | Titanium (Ti) 44.2% |

Mechanical Properties Table

| Mechanical Property |

Nitinol Wire |

| Tensile Strength (MPa) | 900 |

| Yield Strength (0.2% Offset, MPa) | 600 |

| Elongation (%) | 10 |

| Hardness (Rockwell) | B85 |

| Modulus of Elasticity (GPa) | 80 |

| Poisson's Ratio | 0.33 |

| Shear Modulus (GPa) | 30 |

| Density (g/cm³) | 6.45 |

| Reduction of Area (%) | 30 |

| Ultimate Tensile Strength (MPa) | 950 |

Types of Pipes and Tubes

Applications & Uses of Nitinol Wire

- Nitinol Wire used in Sugar Industry.

- Nitinol Wire used in Power Industry.

- Nitinol Wire used in ShipBuilding Industry.

- Nitinol Wire used in Mechanical and Plant engineering.

- Nitinol Wire used in Food, Beverage, and Dairy.

- Nitinol Wire used in Oil and Gas Plant.

- Nitinol Wire used in Process Instrumentation.

Cities we supply Pipes & Tubes in India :-

| Nitinol Wire Supply: |

| Bengaluru |

Chennai |

Hyderabad |

Kolkata |

Mumbai |

Pune |

| Bhopal |

Sri City |

Jamshedpur |

Hosdurg |

Lucknow |

Noida |

| Ahmedabad |

Delhi |

Raipur |

Jaipur |

Surat |

Salem |

| Jamnagar |

Bhubaneswar |

Sivakasi |

Rajahmundry |

Thiruvananthapuram |

Tiruppur |

| Bhiwandi |

Bokaro Steel City |

Bharuch |

Vijaywada |

Firozabad |

Rajkot |

| Cochin |

Ludhiana |

Durgapur |

Panna |

Panipat |

Raipur |

| Bareilly |

Channapatna |

Kharagpur |

Peenya |

Pimpri-Chinchwad |

Nashik |

| Bangalore |

Indore |

Haldia |

Moradabad |

Varanasi |

Rourkela |

| Bhopal |

Sri City |

Jamshedpur |

Hosdurg |

Lucknow |

Noida |

| Bareilly |

Coimbatore |

Kannur |

Nagpur |

Vadodara |

Rudrapur |

| Agra |

Bhagalpur |

Bhilai |

Thane |

Kanpur |

Haldia |

| Angul |

Dibrugarh |

Gwalior |

Patna |

Trivandrum |

Pithampur |

Countries we export Pipes & Tubes worldwide :-

| Nitinol Wire Exporter: |

| United States |

South Africa |

Malaysia |

Bangladesh |

Turkey |

| Bahrain |

Qatar |

UAE |

Africa |

China |

| Nigeria |

Mexico |

Canada |

Venezuela |

United Kingdom |

| Egypt |

Jordan |

Portugal |

Russia |

Vietnam |

| Kazakhstan |

Thailand |

Spain |

Romania |

Philippines |

| Hongkong |

Taiwan |

Japan |

Ukraine |

Chile |

| United States |

South Africa |

Malaysia |

Bangladesh |

Turkey |

| Australia |

Brazil |

Germany |

Singapore |

Sri Lanka |

| Iran |

Saudi Arabia |

Oman |

Kuwait |

Netherlands |

| Belgium |

France |

Italy |

South Korea |

Poland |

| Costa Rica |

Israel |

Iraq |

Madagascar |

Morocco |